#Wire Displacement Sensors

Explore tagged Tumblr posts

Text

Linear Wire Displacement Sensors for AGV Forklifts – Briterencoder

Enhance AGV forklift precision with Briterencoder’s linear wire displacement sensors. Offering durability, real-time position feedback, and seamless integration for optimized material handling.

0 notes

Text

Silken Synapses

Jazz x Reader (NSFW)

AN: Happy Valentines Day. Reader has a dick but no pronouns are used.

The way the city lights filtered in through the blinds of your apartment window made Jazz stare up at you like you had to be the Allspark incarnate.

Streaks of vibrant blue danced over your skin with every bounce, your body leaving your silhouette cast across the wall. Violet caught the hard line of your jaw and optic ridge, and a rose highlights your aft as you rock and move. You looked like you were painted in neons and the midnight hour. And the noises you made? Felt like they were ripped from the stars themselves, bright and calling to his spark in the dark of the night.

Your hips rolled again, and the sound he made was all static and buzz, his vocoder struggling with how his sensors were running wild at the pleasure racing through him. One of your hands slid across his exposed panel, wires all on display for your discretion. And you made good use of such a treat, fingers skimming along rubber, dragging a nail lightly down one until the friction caught, and you opt to instead tug the flat cabling.

Jazz's intake dropped open in a drawn out groan.

“Frag, baby, you're filthy.”

His skittered, scrambled visual field was splintering, fracturing, his view of your form multiplying like a kaleidoscope of delight. Watching your other hand trail down your chest and slowly nearing your own spike- penis? Dick, cock, rod, too many words that made his currently overheated processor scramble to fit in one slot and overwhelm it.

…SPEAKING of fitting in slots, you began bounce on his spike more, slick and warm and- PRIMUS, that, that nasty little trick you kept doing, squeezing and tightening around him before relaxing again and moving quicker. It made Jazz grit his denta, throwing his helm back with a hiss each time.

“Tease…!”

The mass displaced mech was rewarded with a husky, silky chuckle that he swore, up and down, was weaving through his audials and caused lightning to zip down his backstruts. Jazz felt like he was going mad, ESPECIALLY as you looped a digit around a green wire in the upper left quadrant and unplugged it, dragging your tongue along the tip of the metal jack plug and sucking lewdly on it. He knew you wouldn't pull out anything important, he'd marked what could and couldn't be toyed with. But it didn't change the fact that when these were toyed with, they made his EM field buzz and flicker.

“Swear I can feel that. It's like my nerves are all tingling…”

You gasped, biting your lip and arching your back. Fist your member and begin stroking faster as you ride him harder, the sound of the flesh and skin clapping against the steel of his plating and the slick of lube and transfluid making for obscene noises ripped from Jazz's fantasies and sounding like a salacious symphony. His biolights flicker in patterns, that he can barely see through your skin every time he sinks deep into your aft- ass. Spike painfully pressurized and hitting deep within your depths, bullying your prostate pleasurably. Hellishly.

Grunting, he gripped your hips, and began helping you move quicker, venting in puffs and his cooling fans whirring louder.

“You close, my pretty little Porsche?”

“Mhm…!”

“Good.”

Bottom left quadrant had the most wires you could pull, and pull you did. In fact, you looped the whole mass around your hand, and yanked as you gasp and release into your condom. His systems went haywire briefly, optics locked onto the glitchy, iridescent image of you, and Jazz's overload crashed his systems like a powersurge, making the porsche unload into you.

#tf x human#tf x reader#transformers x reader#transformers x human#valveplug#tf x reader smut#tf x human smut#squibs writes#tf jazz#transformers jazz#jazz x reader

70 notes

·

View notes

Text

Transformers Earthspark: Another Place, Another Prison

Star does indeed get his meeting with Hashtag he scored with his deal with Megatron. Although, as most things, it doesn't exactly go favorably. The chaos energy shit and his damn 10k layered trauma ratatouille is not exactly making things easy for anyone. I REALLY want these two to reconcile at some point, yet alas, this is certainly not that chapter-

Also--Bee was absolutely about to be baited into fighting Star at the end before Tag interrupts lmao

Previous Chapter: Lingering Ghosts

First Chapter: A Need For Read

Next Chapter: An Unwanted Sequel

Chapter 5: Perception

Starscream had rounded the perimeter of the cell approximately 175 times now. It was a respectable number to end on, so he decided to take a seat against the wall. Megatron was certainly taking his time in fulfilling his side of their deal. Perhaps he had decided to simply forgo upholding his word. That would be disappointing. Although admittedly unsurprising.

Starscream's wings perked at the sound of pedsteps through the corridor, but drooped when he recognized that it was his audials playing tricks on him again.

“Ey what’s the plan commander? I’m dyin’ in ‘ere!” Swindle complained, and the noise made Starscream’s optic twitch red.

“I’m working on it!” He growled.

“Starscream: Moping.” Soundwave commented just so helpfully as the stoic mech also sat on his aft in the cell across from him.

“I am not!” Starscream’s vocalizer betrayed him with a high pitched squeal, and he cleared his throat. “I do not need to entertain any of you glitches. Just because my processor insists on projecting you, does not make you worthy of my attention. Leave me be and jet yourselves back into space why don’t you.” Starscream waved a servo as if he could send them away with the gesture.

It only partially worked, as Soundwave’s form found it pertinent to displace itself to a less casual moment in time. When Mandroid had been given free reign to select any one of them as lab rodents to be experimented upon. The blue mech’s servos and peds were tightly bound to leave him splayed out upon the ground for scrambling little human pests to defile his circuits. They hadn’t even severed his sensors for the operation. They’d just popped open panels and prodded around like maggots deconstructing a living corpse.

Starscream’s frame locked up as his spark felt constricted in his chassis. His vents had stopped. He knew it wasn’t real. Perhaps he shouldn’t have angered the illusion. Now he was stuck rewatching the disgusting scene as samples of the mech’s frame were being sawed off barbarically, the internal wiring being strewn about, and those cursed injections of more than questionable substances. The array of equipment echoed dreadfully in his audials.

Suddenly, the world spazzed again, and one of the G.H.O.S.T agents hovered sinisterly in front of his cell. Staring. Scrutinizing him with an air of hunger on its faceless mask. Like a predacon reveling in the power it held over its prey. Savoring not just its victory over its victims, but sadistically devouring the gruesome process itself. The creature simply found joy in their suffering, and lingered in a promise for what Starscream knew had happened next.

Then, there was Skullcruncher. Starscream heard the croctobot shift in the cell beside him, and his helm was inadvertently drawn to face it. The frame he saw wasn’t right. The lighting wasn’t right. It was dim and hazy, but he vaguely identified Skullcruncher as he shambled towards the barrier separating them. The sturdy beast was painfully caught between his bot and alt modes. Plating bent, warped, and twisted in ways it should not have been able to manage. His faceplate distorted with shadow and melting metal so that his optics and dentas stuck out in an unnerving, unnatural manner.

The raspy voice box of the creature spoke to him. It sounded like too many different vocalizers at once for him to discern.

“You deserve what has come to you, Starscream. It’s your fault. You didn’t help us. You only helped yourself. How could you?”

Starscream yelped and scrambled back until he hit the opposing corner. His wings vibrated, crimson lightning flickering between them, and he barely registered them scraping against the wall.

“You did this.”

The words dug into his audials and he slapped his servos over his receptors like it could save him. “No no, shut up.” Starscream hissed as he glared at his knees, then his vocalizer cracked a chuckle. “You’re not real! It’s not real!” He sang manically. “You can’t trick me. No no no no…”

“You’ll never escape, Starscream. You have no allies that would bother to help you.”

“Hehe-” His vents were cycling far too quickly to aid his addled processor as he muttered, “I’m not listening to you. I don’t have to listen to you. Leave me alone.”

“...Who are you talking to?”

Starscream shrieked and flung his helm backwards in surprise at the suddenly crisp, external sound that questioned him. His optics shot in its direction to see exactly the Terran he so desperately wanted to see. He excitedly sprung to his peds and spread out his servos earnestly.

“HASHTAG!” Starscream greeted perhaps a bit too loudly, then swiftly stepped closer before finding a bit of hesitation and slowing his approach. “I-it’s so good to see you–heh- how-h-how have you been?? After… well, uh–”

“After you stole the Emberstone, nearly killed everyone I care about, and forced Terratronus to start destroying Witwicky?” She finished snarkily with crossed arms and an angry look on her faceplate.

“Yes… that. But we can put that whole debacle behind us! We each got a couple good jabs at the other– what’s a few bouts of blaster fire between friends, right?” He waved his servos around animatedly and his vocalizer was a bit too high pitched for his liking, but that was a silly concern.

“You’re crazy.” Hashtag stated decidedly with far too much contempt, and continued with bitterness bleeding through her tone, “I can’t believe I ever believed in you! How could you do that!? I see now that you are just– worse than Megatron ever could have been.”

Starscream’s wings flicked stiffly behind him and his widened optics glitched between their red and blue as he took a step back. He was horrified. At what exactly, he couldn’t decide. She hated him– She didn’t understand– She was wrong. His wings shifted up and down erratically to relieve even a fraction of the pent up energy clawing at his spark. His servos shook and his optics darted across different points of his surroundings, occasionally landing on Hashtag before looking away again.

“I- You-!” Starscream had lifted a digit with the intent of confronting the Terran’s accusation, encouraged by that damned chaotic crimson corrupting his vision. But did he really have the right to berate her? A parasite nagged at his impulses that he should crush her voice box for her impertinence. He should tell her just how foolish of a proclamation she had made. Give her a verbal assault equal to the one he’d given Megatron. How dare she turn on him like this.

Yet with his sparing glances at her faceplate, even with the assured determination she held herself with, he saw glimpses of fear in her stance. This deepened the pit in his tank. Was he scaring her somehow? That wasn’t what he wanted. How could he have those thoughts?! Perhaps she did have a right to be angry with him after all…

Starscream in-vented, then tried his best to smile and smooth his vocalizer. “Come now, Hashtag, let’s not be brash.” He chuckled halfheartedly. “I’m sure you don’t mean that! Believe me, it was never my intention to damage you or your terran siblings. All you really had to do was step aside while I– what I mean to say is– i-it wasn’t about you, I just-” Oh that sounded bad didn’t it?

Hashtag scoffed, “Not about me? Woooow, thanks. That totally makes what you did alright. Except it doesn’t. You know, you’re lucky we’ve kept Spitfire and Aftermath from coming in here to give you a piece of their mind! What about what you did to them, huh!? I don’t care if it wasn’t about me, you still hurt and endangered so many people for some stupid power buff!”

Starscream stared at her blankly for some time as her words loaded in his processor. They’ve kept Sprite and A.M. from coming here… that means the sparklings were moving! Of course they saw it fit to come back online as soon as he was out of the picture. He knew it.

Starscream’s grin widened at the revelation, “I KNEW IT!” He said so suddenly that Hashtag flinched in surprise and looked at him with that same strange expression Megatron had worn, paired with a dash of confusion at his proclamation. He straightened himself to regain what composure he could before tilting a servo to enlighten her. “See, I knew those two never required those Embershards to function! I was right! They were just playing a petty, silly little game to get back at me when we were trapped up there in the Titan. Did they just need whatever fuel you Terrans need? Did you somehow collect a higher dose of the chaos energy that I could not? Or did they simply arise after I departed?” He tilted his hip snarkily and crossed his arms. “If that is the case I will have quite the word with Sprite about her rather rude, meager communications she chose to send me instead of contributing.”

Hashtag’s intake hung open stupidly before her faceplate scrunched in bafflement. “...What?”

Starscream thought he had explained himself quite well. He rolled his optics and impatiently urged her to answer his query, “At what point did they decide to come online?”

“Decide?? You killed them! We were only able to bring them back with a crazy idea to toss them into the chaos cloud junk with the spear! Of course anime has never done me wrong and it totally worked– but they weren’t deciding to be dead! What’s wrong with you!?” Hashtag was throwing her servos around in some ill placed frustration as she spouted nonsense.

“They weren’t dead, they were in stasis from their regretable damages.” Starscream tried to clarify. He wasn’t crazy. He knew exactly what was going on.

“Dude you can’t be this delusional. What weird space rock did you eat up there?”

“I’m not delusional.” Starscream snapped with a flash of red in his optics before he reeled himself in again. “If they were permanently offline, then there would have been no possible way Sprite could have pinged my communicator!”

Hashtag blinked and shook her helm as she partially recognized what he’d said. “Sprite…? You mean Spitfire??” She actually looked fondly amused before she forcefully refocused herself, “No– ugh, c’mon man! That makes absolutely no sense. Maybe she was like, haunting you, or something–that would definitely make for some good cinema– but I’m pretty darn sure they were dead-dead for a while there. They looked very dead to me.”

Starscream threw his servos in the air, “Well maybe she was a good actor all along! I’m not crazy!! And I am most definitely not hearing things!!” His wings shuttered as the chaos energy pulled at his circuits. “Believe what you want if you enjoy being wrong–” Lightning shot through his frame and he shook his helm in a hopeless effort to stave the crimson from his optics– “You…You’re just a confused sparkling that doesn’t understand the nuances of the situation– STOP FRAGGING LOOKING AT ME LIKE THAT OR I SWEAR I’LL DESTROY THIS PATHETIC BARRIER!”

That slagger Bumblebee ran up from his post at the sector’s entrance to plant himself between Starscream and Hashtag defensively. “HEY! Cool it Screamer! Don’t make me cut your playdate short!”

The corrupted power of the Emberstone erupted from Starscream’s frame, causing that wretched shaking and haze in his optics. “BUT OUT BUG! This doesn’t concern you!” He growled with a stance rearing for a fight.

“I think it does, actually. Especially with whatever this is.” The bumbling bot whirled a servo in Starscream’s general direction rudely.

“Oh REALLY?” He laughed darkly, “You honestly think you are of any use here?! You could never hope to stand against me, scout. Now step aside. Or do you wish to come in here and prove what little prowess you might possess?”

The bug scoffed, “I’m not going to fight you right now Starscream.”

“Coward.”

Before Bumblebee could respond, Hashtag frantically yelled: “STOP!!” Once she’d gained their attention she in-vented sharply and placed a servo on the bug’s shoulder plating. “Just- c’mon Bee, this was stupid… let’s just go.”

“WHAT? You- you can’t just leave–” Starscream stressed angrily. How dare she try to walk away from their conversation!

“You can’t tell me what to do!” She snapped at him before stomping away down the corridor. The bug stared at Starscream a moment longer before hopping away to catch up with Hashtag.

Blue battled for control of his optics and his vents quickened, then he scrambled as close as he could towards them with an extended servo. “WAIT! Wait– please– w-we can- we can still talk about this- I’m sorry I– I didn’t mean it! Please Hashtag, I’m sorry if I scared you, don’t–don’t leave!”

She only spared him one last glance as she tightly hugged her frame, her faceplate full of hurt that he’d foolishly caused. Then the door closed.

“NO! No…no-” Starscream’s servo slowly lowered partway before balling into a fist, “UGH WHY DID I DO THAT?!” He slammed it against the barrier before slumping down to his knees pathetically with a whine. Then voiced Hashtag’s question in a whisper, “What is wrong with me…?”

Nothing about that had gone as it should have.

Starscream had wanted to have a casual, friendly conversation where they could possibly reconcile. Where maybe he could’ve gotten her to understand, and forgive him. Perhaps even get her to pass a good word to the Autobots! But then he had to go and open his big fat glossia, and say literally all the wrong things.

When had it devolved so horribly?? He hadn’t thought it was going that bad! Sure, It had often periodically become more confrontational than he had hoped, but he should have been prepared for that. He should have rehearsed his approach better. Why hadn’t he prepared? He’d had the time, hadn’t he?

Yet all he’d managed to do was frag things up more than they already were. Now how was he going to get out of here?! Jump one of the glitches if they decide to bring him energon…? That had too many ways to go awry, but it might be his only chance.

Or… Perhaps, he could get this Primus damned power that infected him to actually be useful…

#starscream#earthspark starscream#hashtag#earthspark hashtag#bumblebee#earthspark bumblebee#transformers earthspark#transformers#fanfic#tf fanfic#Vibrates intensely#boi is nanners and in denial#the guilt is and regret is manefesting

47 notes

·

View notes

Text

Anonymous Submission to North Shore Counter-Info Earlier this week a group of people sabotaged Gastops’ factory in Ottawa, the only place in the world where engine sensors are produced for Lockheed’s F-35 combat jets — including the ones dropping 2,000 pound bombs on Gaza. We cut the wiring inside all of the heat pumps on the Gastops roof, locked them out with official Ministry of Health and Safety lock-out tags, shut off the gas, broke the handles for their systems, and cut the lines to their backup communication system on the way out. The following letter and photos were left on site:

It’s worth noting that we disabled their heat pumps as it begins to get cold here in Ottawa and as displaced people in Gaza and Lebanon plead with us to help them secure shelter, blankets, clothing, as they freeze in displacement camps. Earlier this month an Ottawa neighbour lost her uncle while he returned to his home in Gaza attempting to bring back blankets for the children so they would not freeze to death. He was murdered by air strike while doing so, likely by an F-35 that Gastops supplies parts to. People growing tired of politicians continuing to support the slaughter of civilians in Palestine and Lebanon will continue to escalate actions seeking peace and an end to these war crimes.

Love to see some fellow anarchists hit 'em where it hurts.

19 notes

·

View notes

Text

The Psychology of Data Adoption: Why Manufacturing Teams Resist Analytics and How to Overcome It

In the era of Industry 4.0, manufacturing data analytics has become essential for competitive advantage. Yet, despite proven ROI and clear benefits, many manufacturing teams resist adopting data-driven approaches. The challenge isn't technical—it's psychological.

The Invisible Barriers to Analytics Adoption

The "Gut Feeling" Culture

Manufacturing professionals have decades of experience making split-second decisions based on intuition, visual cues, and hands-on expertise. When data analytics and manufacturing intersect, it often creates cognitive dissonance. Workers who've successfully operated machines for years may feel their knowledge is being questioned or replaced by algorithms.

This resistance stems from what psychologists call "experiential processing"—the brain's preference for familiar, emotion-based decision-making over analytical thinking.

Fear of Job Displacement

The most significant psychological barrier is existential fear. Manufacturing workers often perceive manufacturing data analytics as a threat to job security. This fear triggers defensive behaviors, including:

Selective data reporting

Resistance to sensor installation

Skepticism toward analytical insights

Preference for manual processes

Status Quo Bias

Humans are naturally wired to prefer familiar situations. In manufacturing environments where the "if it ain't broke, don't fix it" mentality prevails, introducing analytics can feel unnecessarily disruptive. This bias makes teams focus on potential risks rather than benefits.

Understanding the Psychological Resistance

Cognitive Overload

Manufacturing environments are already information-rich. Adding dashboards, alerts, and reports can overwhelm workers who are accustomed to processing information through physical senses—sight, sound, and touch. The human brain can only process limited information simultaneously, and data analytics and manufacturing integration often exceed this threshold.

Loss of Autonomy

Experienced operators take pride in their independence and decision-making authority. When analytics systems suggest actions or flag potential issues, workers may perceive this as micromanagement, leading to psychological reactance—the tendency to resist when feeling controlled.

Imposter Syndrome

Many manufacturing professionals feel inadequate when confronted with sophisticated analytics tools. This creates anxiety and resistance, as individuals fear appearing incompetent in front of colleagues or supervisors.

Strategies to Overcome Psychological Barriers

Start with Collaborative Implementation

Instead of imposing manufacturing data analytics top-down, involve workers in the design and deployment process. When employees help select sensors, define metrics, and interpret results, they develop ownership and reduce resistance.

Practical Approach:

Form cross-functional analytics teams

Include floor workers in vendor selection

Let operators define what "normal" looks like in their data

Emphasize Augmentation, Not Replacement

Frame analytics as a tool that enhances human expertise rather than replacing it. Position data analytics and manufacturing as a partnership where human judgment guides analytical insights.

Communication Strategy:

Use phrases like "data-assisted decisions" instead of "automated decisions."

Highlight how analytics can prevent worker injuries

Show how data validates their existing expertise

Provide Psychological Safety

Create an environment where mistakes and questions are welcomed. Many workers fear that analytics will expose their errors or inefficiencies, leading to punishment.

Building Safety:

Use initial data for improvement, not performance evaluation

Celebrate learning from analytical insights

Share success stories from peer organizations

Gradual Exposure and Training

Implement manufacturing data analytics incrementally, allowing teams to build confidence and competence gradually. Start with simple metrics before introducing complex predictive models.

Phased Approach:

Begin with descriptive analytics (what happened?)

Progress to diagnostic analytics (why did it happen?)

Advance to predictive analytics (what might happen?)

Address Individual Concerns

Recognize that resistance is often personal. Some workers may struggle with technology, while others fear losing career advancement opportunities.

Individual Support:

Provide personalized training programs

Create mentorship opportunities

Offer career development paths that incorporate analytics skills

Creating a Data-Driven Culture

Leadership Modeling

When manufacturing leaders consistently use data in their decision-making and openly discuss analytical insights, it normalizes the behavior throughout the organization.

Recognition and Rewards

Acknowledge and celebrate instances where manufacturing data analytics leads to improvements, cost savings, or problem-solving. Make data-driven decisions visible and rewarded.

Continuous Communication

Regularly share how data analytics and manufacturing integration have benefited the organization, individual workers, and customers. Transparency builds trust and reduces fear.

Conclusion

The success of manufacturing data analytics depends more on psychology than technology. By understanding and addressing the human factors that drive resistance, manufacturers can create environments where analytics and human expertise work synergistically.

Remember: the goal isn't to eliminate human judgment but to enhance it with data-driven insights. When workers feel valued, supported, and empowered by analytics rather than threatened, adoption becomes not just possible but enthusiastic.

The future of manufacturing belongs to organizations that master both the technical aspects of analytics and the psychological aspects of change management.

0 notes

Text

Engineering the Edge: What Separates Good from Great in Modern Factories

Behind every high-performance machine, isn’t there a silent force powering it — reliably and relentlessly?

In the background of India’s bustling manufacturing sectors, from plastics and packaging to pharmaceuticals and automotive, one name has been quietly revolutionizing the way industries manage heat. With decades of technical expertise and an unwavering focus on engineering innovation, Elmec has become a trusted partner in delivering smart, efficient, and custom-built industrial heating solutions tailored for the demands of a modern industrial world. From plastics and pharmaceuticals to food processing, packaging, chemicals, and automotive, Elmec’s heating systems power the core of industrial operations. What makes Elmec stand out among Indian heater manufacturers is its commitment to variety, performance, and customization.

At the heart of their offerings are Ceramic and Mica Band Heaters, crafted with precision using Nickel Chrome resistance wires embedded in Mica or Micanite and covered with a durable metal casing. These heaters are built to last and ensure even heat transfer, making them ideal for machines like extruders, injection molding, and blow molding equipment. Whether standard sizes or tailor-made, Elmec provides the perfect fit for every setup.

Their range of Tubular Heaters is designed for toughness and versatility. Made from high-grade stainless steel and alloys like Incoloy and Inconel, these heaters perform reliably in tough environments. They are available in various formats such as Chemical Immersion Heaters, Finned Air Heaters, and Teflon-coated versions, depending on the application.

Elmec also offers compact and efficient Cartridge Heaters for precision heating in tight spaces. With models ranging from High-Density and Low-Density to Split-Type, these heaters meet the specific needs of industries requiring accurate temperature control. The Split-Type Cartridge Heater, in particular, is widely appreciated in aluminum extrusion systems for its easy maintenance and consistent output.

Taking a step into advanced heating technologies, Elmec is also a pioneer in Infrared Heating Solutions. Their collection includes ceramic infrared elements, quartz tube heaters, and high-efficiency panel heaters. These infrared heaters provide fast, focused, and energy-saving heating for applications such as thermoforming, paint curing, drying, and PET preform heating.

In addition to core heaters, Elmec offers highly specialized solutions like Hot Runner and Manifold Heaters, essential for maintaining temperature uniformity in plastic injection molds. These heaters help reduce cycle times, improve part quality, and lower production waste.

To help customers maintain full control over their heating processes, Elmec provides advanced electronic control systems such as PID temperature controllers, Hot Runner Controllers, and Power Regulators — helping to streamline energy use while keeping performance consistent.

Completing the package are a range of accessories and process enhancers, including Thermocouples, Pressure and Displacement Sensors, Insulation Jackets, and Hopper Dryers. These tools not only improve process efficiency but also add an extra layer of safety and automation.

What truly sets Elmec apart is its engineering-driven mindset. Every product is designed not just to function — but to solve problems, optimize energy use, and boost productivity. Whether it’s a high-volume manufacturing line or a niche industrial process, Elmec stands out as a dependable partner, providing intelligent, robust, and customized heating solutions for India’s growing industries

0 notes

Text

Abstract Vibration testing is a crucial element in validating the reliability, structural integrity, and durability of components and finished products throughout their operational lifespan. This paper discusses how vibration testing equipment, specifically the LISUN LVD-100KG Electrodynamic Vibration Generator System, plays a pivotal role in determining product resistance to real-world mechanical stresses. By simulating various vibration profiles across multiple axes, this system helps manufacturers meet international standards and improve product designs. Comprehensive performance data, testing configurations, and industry applications are explored alongside comparative analysis, highlighting the significance of modern vibration testing equipment in contemporary quality assurance processes. 1. Introduction In an increasingly demanding consumer and industrial market, ensuring the longevity and robustness of electronic and mechanical products is more critical than ever. Vibration testing equipment serves as a simulation platform that helps evaluate how products behave under operational vibrations. Whether the product is destined for automotive, aerospace, electronics, or household use, it is expected to perform reliably despite constant exposure to mechanical stress. The LISUN LVD-100KG Electrodynamic Vibration Generator System is designed for high-performance vibration simulation, enabling precise testing of product response to mechanical stresses. This paper investigates the utility of such systems, discusses standard testing procedures, and provides analytical results from typical testing scenarios. 2. Importance of Vibration Testing Equipment in Product Development Vibration testing is a foundational step in product development and certification, helping in: • Detecting structural weaknesses • Identifying premature failure risks • Improving packaging designs • Optimizing component layout and materials Without proper vibration simulation, products may suffer from early failures due to resonance, fatigue cracks, or misalignments. Vibration testing equipment facilitates both developmental diagnostics and final validation. Electrodynamic Vibration Generator System LVD-100KG 3. Overview of LISUN LVD-100KG Electrodynamic Vibration Generator System The LISUN LVD-100KG system provides programmable vibration profiles that comply with international standards like IEC, MIL-STD, ISO, and ASTM. The system supports vertical and horizontal test modes, making it suitable for a wide range of product testing applications. Key Features: Parameter Specification Max Load Capacity 100 kg Frequency Range 2–5000 Hz Max Acceleration 100 g Max Displacement 25 mm (peak to peak) Vibration Mode Sine, Random, Shock Axis Support X, Y, Z Cooling System Air-cooled Controller Interface PC-based with programmable sweep profiles The system’s ability to simulate shock and continuous vibration makes it ideal for evaluating resonance, looseness, and material fatigue in components like circuit boards, battery packs, vehicle modules, and consumer electronics. 4. Test Methodologies Supported by Vibration Testing Equipment The LVD-100KG supports several standardized testing methods: 4.1. Sinusoidal Sweep Test Used to find the natural frequency and potential resonances. 4.2. Random Vibration Test Mimics real-world vibration environments such as transportation or operational engine noise. 4.3. Shock Test Applies abrupt pulses to assess resistance to sudden impacts or drops. 4.4. Dwell Test Applies vibration at a fixed frequency for extended durations to study fatigue. 4.5. Transportation Simulation Reproduces shipping and handling conditions to validate packaging and product robustness. 5. Application Scenarios Vibration testing equipment is used across various sectors: Industry Test Objective Example Components Automotive Validate mechanical stability ECU, Sensors, Dashboard Aerospace Ensure performance in flight Avionics, Wiring, Brackets Electronics PCB durability & connector stability Mobile Devices, Laptops Household Appliances Noise and vibration reduction Washing Machines, Compressors Lighting Assess joint and housing endurance LED Drivers, Bulbs 6. Case Study: LED Driver Vibration Test Objective: To assess mechanical robustness and solder joint integrity of LED drivers under operational vibration conditions. Equipment Used: • LISUN LVD-100KG Vibration Testing Equipment • Acceleration sensors • Data acquisition system Test Parameters: Test Mode Sine Sweep Frequency Range 10–1000 Hz Acceleration 10 g Duration 2 hours per axis Axes Tested X, Y, Z Results Summary: Axis Observations X Minor casing vibration, no structural failures Y Slight connector loosening noted Z No anomalies detected The test highlighted potential design improvements in connector attachment methods to enhance product longevity. 7. Software Capabilities and Control Flexibility The LVD-100KG system includes intuitive, PC-based software that offers: • Automatic frequency sweep • Custom test profiles • Real-time data logging • Alarm and shutdown features for test safety • Report generation in CSV and PDF formats Such automation ensures repeatability and minimizes human error, increasing overall test reliability. 8. Compliance and Standards The LVD-100KG meets various global testing standards: Standard Application IEC 60068-2-6 Environmental testing MIL-STD-810G Military-grade vibration tests ISO 16750 Automotive electrical and mechanical requirements GB/T 2423.10 Chinese national vibration test standard By adhering to these benchmarks, the system ensures product acceptance in both domestic and international markets. 9. Comparative Analysis with Competing Systems Feature LISUN LVD-100KG Competitor A Competitor B Max Load 100 kg 80 kg 60 kg Frequency Range 2–5000 Hz 5–3000 Hz 10–4000 Hz Acceleration Up to 100 g 60 g 75 g Cost-effectiveness High Medium Medium Software Control Advanced Basic Intermediate LISUN’s LVD-100KG stands out for its high acceleration capacity, wider frequency range, and superior control software, making it a cost-effective solution for comprehensive vibration testing. 10. Conclusion Vibration testing equipment is essential in ensuring the long-term stability and reliability of electronic and mechanical components. The LISUN LVD-100KG Electrodynamic Vibration Generator System offers advanced testing features, comprehensive standard compliance, and exceptional control flexibility, making it a premier choice for developers and quality control engineers across industries. By simulating real-world mechanical stress environments, the LVD-100KG helps manufacturers uncover potential weaknesses, improve product designs, and meet global reliability standards. This ultimately leads to safer, longer-lasting products that perform reliably throughout their lifecycle. References LISUN Group. LVD-100KG Electrodynamic Vibration Generator System. . Available: https://www.lisungroup.com/products/led-test-instruments/dc-electronic-load.html IEC 60068-2-6: Environmental testing – Vibration (sinusoidal) MIL-STD-810G: Environmental Engineering Considerations and Laboratory Tests ISO 16750: Road vehicles – Environmental conditions and testing for electrical and electronic equipment GB/T 2423.10-2008: Basic environmental testing procedures Read the full article

0 notes

Text

Automated Production and Testing Processes of Rocker Switches

1. Introduction

With the rapid development of industrial automation, the manufacturing process of rocker switches has undergone a transformation from traditional manual production to highly automated, precision-controlled production lines. This shift not only improves production efficiency and product consistency but also enhances the competitiveness of enterprises in the market. This article will provide a comprehensive overview of the automated production and testing processes of rocker switches, including automated terminal insertion, automated spot welding, automated LED placement, as well as contact resistance testing, travel and pressure testing, continuity time measurement, and industrial vision-based appearance inspection. These technologies represent a high degree of integration between mechanical systems, electronic control, and intelligent algorithms.

2. Automated Assembly Processes in Rocker Switch Production

2.1 Automated Terminal Insertion

Terminal insertion is one of the most critical steps in rocker switch production. Traditional manual insertion is prone to positional deviation and insertion force instability, which may cause defective contact or product rejection. Modern production lines adopt servo-controlled automated terminal insertion systems, which use multi-axis manipulators to position terminals precisely. High-precision optical sensors ensure insertion depth and orientation consistency.

For instance, the system automatically picks the copper terminal from the feeder, precisely aligns it with the switch base, and inserts it at a controlled speed and pressure. This ensures the mechanical integrity of the assembly and avoids micro-damage to the plastic shell, laying a solid foundation for subsequent spot welding.

2.2 Automated Spot Welding

Spot welding ensures the electrical connection between terminals and leads. The automated welding station uses resistance spot welding controlled by pulse current and time curves to precisely fuse metal interfaces.

Advanced systems are equipped with closed-loop current monitoring and displacement sensors, allowing real-time compensation for contact surface changes, thus ensuring stable and low-resistance welded joints. Additionally, the system is integrated with fume extraction and safety monitoring modules, improving the working environment and overall safety.

2.3 Automated LED Placement

Rocker switches with indicator lights require precise LED placement. Automated LED placement machines use high-speed pick-and-place heads and machine vision calibration to accurately position the LED within the switch cavity. The polarity and brightness are verified in real time during the process to ensure optical performance and visual consistency.

This process ensures that the LED does not shift during encapsulation or welding, maintaining long-term reliability and aesthetic appeal of the final product.

3. Automated Testing Systems for Rocker Switches

To ensure product reliability, each rocker switch must undergo comprehensive electrical and mechanical performance tests before leaving the factory.

3.1 Contact Resistance Test

The contact resistance test evaluates the resistance value across the conductive path under rated pressure. Modern automated testing equipment uses a 4-wire Kelvin method to eliminate lead resistance influence. The system can test multiple switches simultaneously, display resistance distribution curves in real-time, and automatically classify unqualified products.

Typical requirement: contact resistance < 50 mΩ (depending on the application scenario).

3.2 Travel and Pressure Test

Travel and pressure tests ensure the rocker switch provides the correct tactile feedback. High-precision linear actuators simulate human finger pressing motion, while pressure sensors and displacement encoders collect force-displacement data.

This allows evaluation of stroke range (e.g., 1.8–2.5 mm), actuation force (e.g., 300–600 gf), and pressing smoothness. Abnormalities such as mechanical jamming, misalignment, or inconsistent feedback can be identified and rejected automatically.

3.3 Continuity Time Measurement

Continuity time refers to the response speed of the switch after actuation. The test system uses high-speed data acquisition cards to detect signal transition points and calculate the time difference between actuation and circuit conduction.

This indicator is especially important for automotive and industrial control applications, where millisecond-level response times are required.

4. Visual Inspection and Intelligent Defect Detection

4.1 Industrial Vision System Introduction

Visual inspection replaces traditional manual quality checks, using high-resolution cameras, lighting modules, and image recognition algorithms to inspect every rocker switch.

It can detect:

Missing parts

Scratches or deformation on the housing

Logo misalignment or blurring

Incorrect assembly (e.g., misaligned rockers, LED offset)

4.2 High Efficiency and Accuracy

For example, a dual-camera system combined with a rotary conveyor can inspect 120 pieces per minute. The system achieves a detection accuracy of 0.05 mm, capable of identifying minute cracks or flash edges on plastic parts.

Deep learning algorithms further enhance recognition ability by learning from real production defects, continuously optimizing detection logic.

5. Traceability and Data Integration

All testing data and inspection results are integrated into the MES (Manufacturing Execution System), enabling full traceability. This helps:

Identify root causes of quality issues quickly

Analyze yield trends

Refine production parameters in real time

By applying barcode/QR code identification to each unit, data from insertion, welding, testing, and inspection can be correlated with the specific product batch, greatly enhancing quality control and accountability.

6. Conclusion

The automated production and testing processes of rocker switches represent the future trend of smart manufacturing in the electromechanical components industry. From terminal insertion to visual inspection, each step is carefully controlled and monitored, improving production efficiency, product quality, and cost-effectiveness. With continued development in industrial AI and robotics, the production of rocker switches will become even more intelligent, flexible, and scalable, helping enterprises meet the diverse and demanding needs of global markets.

en.dghongju.com

0 notes

Text

Special Hazards Fire Protection Safeguarding High-Risk Environments

What is Special Hazards Fire Protection?

Special hazards fire protection refers to the systems and practices used to detect, suppress, and control fires in areas where conventional sprinkler systems are inadequate or inappropriate. These areas typically include:

Power generation plants

Data centers and server rooms

Chemical processing facilities

Aircraft hangars

Marine environments

Clean rooms and laboratories

Museums and art storage

Industrial machinery enclosures

Each of these environments presents distinct fire risks due to the nature of the materials or equipment involved. For instance, water from a traditional sprinkler system can severely damage electronic equipment or react dangerously with certain chemicals. Special hazards systems are engineered to handle these challenges effectively.

Components of a Special Hazards Fire Protection System

A comprehensive special hazards fire protection system includes several key components:

1. Fire Detection and Alarm Systems

Rapid detection is crucial in special hazard environments. Advanced smoke, heat, and flame detectors are used, often employing technologies such as:

Aspirating Smoke Detection (ASD): These systems continuously sample air and are highly sensitive to even small amounts of smoke, making them ideal for clean rooms and server spaces.

Infrared and Ultraviolet Flame Detectors: These devices detect flames quickly and are often used in environments where fires can ignite and spread rapidly.

Linear Heat Detection: Useful for protecting cable trays and conveyor belts, this type of system detects heat along a wire or sensor cable.

2. Suppression Systems

Depending on the nature of the hazard, suppression agents can vary widely:

Clean Agents: Non-conductive, non-corrosive, and residue-free, clean agents like FM-200, Novec 1230, and CO₂ are used in data centers, telecommunication rooms, and control panels.

Foam Systems: Ideal for flammable liquid storage and aircraft hangars, foam forms a blanket over the fire, cutting off oxygen and preventing re-ignition.

Dry Chemical Systems: These are fast-acting systems used for Class B (flammable liquids and gases) and Class C (electrical) fires.

Water Mist Systems: They use high-pressure water to create a fine mist that cools the fire and displaces oxygen without damaging equipment like a traditional sprinkler might.

3. Control and Notification Panels

Centralized control panels monitor the fire protection systems and provide alerts. These panels are designed to integrate with building management systems and can initiate emergency shutdowns or notify first responders automatically.

4. Manual Release Stations and Alarms

In addition to automatic activation, most systems include manual pull stations for added safety, allowing personnel to activate suppression systems in case of a confirmed fire.

Applications and Industry Use Cases

Data Centers and Server Rooms

In environments where downtime equals significant financial loss, clean agent suppression systems are the go-to solution. These systems act quickly and leave no residue, ensuring minimal disruption to operations.

Power Generation Facilities

Turbine enclosures and transformer rooms are protected using CO₂ or water mist systems, which can suppress fires without harming expensive electrical equipment.

Chemical and Petrochemical Plants

These facilities often deal with volatile substances. Foam and dry chemical systems are commonly used, tailored to the specific flammable or reactive materials present.

Aviation and Marine Industries

Aircraft hangars and ship engine rooms face high fire risk. High-expansion foam and water mist systems are employed to rapidly suppress fires without damaging sensitive equipment or cargo.

Benefits of Special Hazards Fire Protection

1. Tailored Solutions

Each system is designed to meet the unique risks of a particular environment. This customization ensures that the protection is both effective and efficient.

2. Rapid Fire Suppression

Special hazards systems are designed for fast activation and response, minimizing fire damage and reducing business downtime.

3. Equipment and Asset Protection

Using appropriate suppression agents like clean gases or water mist helps avoid secondary damage that traditional water-based systems might cause.

4. Regulatory Compliance

Many industries are required to meet specific fire protection standards. Special hazards systems ensure compliance with codes such as NFPA 2001 (Clean Agent Fire Extinguishing Systems), NFPA 12 (CO₂ Systems), and others.

Challenges in Special Hazards Fire Protection

Despite its benefits, special hazards fire protection presents several challenges:

Complex Design Requirements: Engineers must deeply understand the protected environment and tailor systems precisely.

Cost: These systems are more expensive to design and install compared to traditional fire suppression systems.

Training: Facility personnel need specific training to operate and maintain special hazard systems safely.

Regulatory Hurdles: Navigating the numerous fire protection codes and standards can be challenging without expert guidance.

Choosing the Right Fire Protection Partner

Implementing an effective special hazards fire protection system requires collaboration with experienced professionals. When choosing a fire protection partner, look for:

Proven industry experience

Compliance with NFPA and local fire codes

Capabilities in system design, installation, and maintenance

Strong track record of system reliability and customer support

Conclusion

Special hazards fire protection is a critical investment for industries operating in high-risk environments. It offers precise, efficient, and reliable fire suppression tailored to the specific challenges of sensitive or volatile settings. As technology and operational complexity increase, the demand for specialized fire protection solutions continues to grow. By adopting the right systems and working with knowledgeable experts, businesses can ensure safety, minimize downtime, and protect valuable assets from the devastating impact of fire.

0 notes

Text

CANbus Linear Draw Wire and Cable Displacement Sensor Transducer

Key features

Exceptional Durability: Built for 5 million fatigue cycles, ensuring prolonged operational life.

Advanced Digital Communication: Utilizes CANbus interface for reliable absolute position sensing and power-off memory, ensuring data retention and robust communication.

Durable Wire Outlet: Enhanced with ceramic materials to improve wear resistance and extend the life of the steel wire rope.

Data Interfaces: Equipped with CANbus communication for seamless data integration, making it ideal for complex systems requiring high-precision feedback.

High-Quality Construction: Features a 0.8mm diameter, imported flexible stainless steel wire rope with a nylon coating to minimize friction and improve longevity.

Superior Pull Head Design: Innovative fixation method provides a tensile limit 10 times greater than conventional models, accommodating up to a 15° angle deviation.

User-Friendly Configuration: Allows for easy parameter settings via CANbus protocol or software, simplifying configuration and operation.

Versatile Operation Modes: Supports query and auto-return modes with position and speed feedback. Fully programmable for baud rate, positioning functions, counting direction, and speed feedback.

Visit https://briterencoder.com/product/displacement-draw-wire-encoder-and-sensor-with-canbus-communication/ for more.

0 notes

Text

LVDT Coil Winders: Precision and Innovation in Winding Technology

Coil winding is a critical process in manufacturing components for electrical and electromagnetic systems. Among the various winding equipment, LVDT (Linear Variable Differential Transformer) coil winders stand out for their precision and efficiency. These machines cater to industries requiring unparalleled accuracy, such as aerospace, medical devices, and automation. Let’s delve into the technical aspects of LVDT coil winders and their pivotal role in modern winding processes.

What Are LVDT Coil Winders?

LVDT coil winders are specialized machines designed to wind coils used in Linear Variable Differential Transformers. LVDTs are electromechanical sensors that measure linear displacement with high accuracy. To achieve optimal performance, these sensors rely on precisely wound coils, which are manufactured using advanced coil winder technology.

Key Features of LVDT Coil Winders

High Precision Winding: LVDT coil winders are equipped with programmable controls to ensure uniform tension and pitch throughout the winding process. This accuracy minimizes signal distortion and enhances the performance of the final product.

Automated Processes: Modern LVDT coil winders incorporate automation to handle complex winding patterns. These machines can wind fine wires with diameters as small as 10 microns, essential for high-sensitivity applications.

Customizable Configurations: From multi-spindle designs to versatile tooling, these machines can adapt to various coil specifications, ensuring compatibility with different LVDT models.

How LVDT Coil Winders Work

Core Components:

Tension Control System: Maintains consistent tension, preventing wire breakage or overlapping.

Rotational Mechanism: Allows precise control of spindle speed for even winding.

Guidance System: Directs the wire with sub-millimeter accuracy, critical for achieving the required winding density.

Process Overview:

Setup: The operator inputs specifications such as wire diameter, number of turns, and pitch into the machine’s control panel.

Tension Adjustment: The tension control system ensures the wire remains taut without snapping.

Winding: The machine executes the winding process, guided by pre-programmed instructions.

Quality Check: Advanced systems verify the coil’s dimensions and consistency before it moves to the next production stage.

Applications of LVDT Coil Winders

Aerospace Industry

In aerospace, LVDTs are integral to flight control systems. LVDT coil winders ensure these sensors meet stringent reliability and precision standards.

Medical Devices

LVDTs in medical imaging equipment demand ultra-fine coils. The high precision of these winders ensures optimal signal output, essential for accurate diagnostics.

Industrial Automation

Robust and accurate LVDTs are vital for industrial automation. Coil winders play a crucial role in manufacturing these sensors, ensuring they perform flawlessly in demanding environments.

Benefits of Using LVDT Coil Winders

Enhanced Efficiency: Automated features reduce production time while maintaining high quality.

Consistency: Uniform winding eliminates variability, ensuring each coil meets exacting standards.

Scalability: Adaptable to produce coils of various sizes and specifications for diverse applications.

The Role of LVDT Coil Winders in LV Winding Machines

While primarily focused on LVDT coil production, these winders share technological synergies with LV winding machines. Both rely on precision and automation to meet industry demands. For instance, a Coil Winder designed for LV applications benefits from advancements in LVDT winding technology, ensuring superior performance across electrical applications.

Conclusion

LVDT coil winders exemplify the fusion of engineering precision and technological innovation. Their ability to produce high-quality coils underpins the performance of critical systems in aerospace, medical, and industrial applications. As technology advances, these machines will continue to redefine standards in the coil winding industry.

What future advancements could further revolutionize winding equipment and their applications? Share your thoughts below!

0 notes

Text

Importance of Fire Fighting Systems in Large-Scale Data Centers

Data centers are the backbone of countless businesses and services, providing the infrastructure necessary for storing and processing enormous volumes of information. However, these highly complex facilities face a significant operational risk—fire hazards. The potential damage from fire in a data center goes beyond physical destruction, potentially resulting in data loss, service interruptions, and economic setbacks. Consequently, robust fire fighting systems are indispensable for safeguarding these vital infrastructures.

The Unique Fire Risks in Data Centers

Data centers house dense arrays of servers, networking equipment, and power systems that operate continuously, generating substantial heat. Despite state-of-the-art cooling systems, the combination of high temperatures, electrical wiring, and flammable materials, such as plastic cables, creates a heightened risk of fire. Furthermore, due to their sensitive nature, these environments require fire suppression methods that avoid damaging equipment or disrupting operations.

Key Components of Fire fighting Systems in Data Centers

To mitigate the risks, firefighting systems in data centers are designed with a multi-layered approach, incorporating fire prevention, early detection, suppression, and containment strategies. Below are the primary components:

Fire Detection Systems

Very Early Smoke Detection Apparatus (VESDA): Data centers use advanced smoke detection systems like VESDA that can identify even minuscule traces of smoke at the incipient stage of a fire. These systems analyze air samples continuously, providing early warnings and allowing prompt intervention.

Heat Sensors: In areas where smoke detection may be insufficient, such as server racks or power rooms, heat sensors monitor temperature fluctuations and trigger alarms if unusual changes occur.

Fire Suppression Systems

Clean Agent Fire Suppressants: These are non-conductive and residue-free chemicals, such as FM-200 and Novec 1230, specifically designed for sensitive environments like data centers. They extinguish fires by removing heat or displacing oxygen while ensuring no damage to equipment.

Inert Gas Systems: Gases like nitrogen and argon are also used in fire suppression. They reduce oxygen concentration to a level that cannot support combustion but remains safe for humans during short exposures.

Water Mist Systems: For facilities where gaseous suppression isn’t viable, water mist systems use fine droplets to cool the flames and reduce oxygen levels. Unlike traditional sprinklers, water mist minimizes the risk of equipment damage.

Fire Containment Features

Compartmentalization: Physical barriers, such as fire-rated walls and doors, limit the spread of fire to specific zones.

Fire-Resistant Materials: Using materials with high fire resistance in cabling, server racks, and other infrastructure helps reduce fire hazards.

Monitoring and Management

Fire Alarm Systems: Integrated alarm systems provide real-time alerts and connect to centralized monitoring systems, ensuring rapid response by on-site teams or fire departments.

Emergency Power Shutoff: In case of fire, automatic systems may cut power to affected zones to prevent further ignition.

Best Practices for Fire Safety in Data Centers

Proactive Fire Risk Assessments Conduct regular fire risk assessments to identify vulnerabilities and ensure compliance with local and international fire safety standards, such as NFPA 75 (Standard for the Fire Protection of Information Technology Equipment).

Redundant Suppression Systems Deploy multiple layers of fire suppression systems to create redundancy. For example, pairing clean agent systems with inert gas or water mist ensures comprehensive coverage.

Routine Maintenance Regular inspection and maintenance of fire safety equipment are crucial to ensure reliability. Malfunctioning sensors or depleted suppression agents can compromise safety during emergencies.

Staff Training Train staff in fire safety protocols, including the use of extinguishers, evacuation procedures, and communication with emergency services. Well-trained personnel can make critical decisions to mitigate fire damage.

Integration with Building Management Systems (BMS) Integrating firefighting systems with the facility’s BMS allows centralized monitoring and automated responses, enhancing overall efficiency and safety.

The Role of Emerging Technologies

Innovations in fire fighting systems continue to enhance safety in data centers. Technologies such as artificial intelligence and IoT are playing an increasing role in fire prevention and management:

AI-Driven Fire Detection: Machine learning algorithms analyze sensor data to predict fire risks, enabling preemptive measures.

IoT-Enabled Monitoring: Sensors connected via IoT networks provide real-time data on temperature, smoke levels, and equipment status, ensuring constant vigilance.

Robotic Firefighting Systems: In large data centers, autonomous robots equipped with fire suppression tools can navigate tight spaces and extinguish fires rapidly without endangering personnel.

Challenges in Implementing Fire Fighting Systems

Despite advancements, data centers face challenges in implementing fire safety measures. These include high installation and maintenance costs, potential disruptions during upgrades, and the complexity of retrofitting older facilities with modern systems. Balancing fire safety with environmental sustainability is another challenge, as traditional fire suppressants may have a high global warming potential (GWP).

Conclusion

Fire fighting systems in data centers are a cornerstone of operational resilience. By combining early detection, advanced suppression techniques, and proactive risk management, data centers can protect their critical assets while ensuring uninterrupted service. As technology evolves, integrating intelligent, sustainable fire safety solutions will be essential to meet the demands of future data center operations.

0 notes

Text

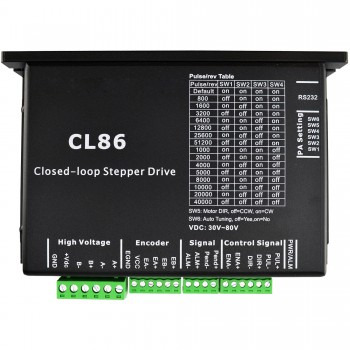

Solutions to faults during operation of stepper motor drivers

1.Basic understanding of stepper motor drivers A stepper motor driver is an actuator that converts electrical pulses into angular displacements. It drives the stepper motor to rotate a fixed angle in the set direction by receiving control signals. The stepper motor driver is an important component of the stepper motor system, responsible for converting the control signal into the current and voltage required by the stepper motor to drive the motor for precise angular or linear displacement. The working principle of the stepper motor driver is to convert the input pulse signal into a drive current signal to control the angular displacement of the stepper motor. The speed of the motor is proportional to the pulse frequency, so the speed can be accurately adjusted by controlling the pulse frequency, and the positioning can be accurately achieved by controlling the number of pulses. The stepper motor driver has high positioning accuracy and stability, and can subdivide each step into smaller steps through the subdivision function, thereby improving positioning accuracy and stability.

2.The main structure of the stepper motor driver 1.Ring distributor. Generate the switching waveform signal processing of the motor in different states according to the requirements of the input signal. Perform PWM modulation on the switching signal waveform generated by the ring distributor and filter and shape the related waveform. 2.Protection circuit. When the winding current is too large, a shutdown signal is generated to shut down the main circuit to protect the motor driver and motor winding. 3.Sensor. Real-time monitoring of the position and angle of the motor, and the signal generation device is transmitted back.

3.Solutions to faults during operation of stepper motor drivers 1.The motor does not rotate or rotates slowly: The stepper motor driver needs to receive the correct pulse signal to control the motor rotation. If the motor does not rotate or rotates slowly, first check whether the pulse signal source is working properly, ensure that the driver input terminal is connected correctly, and check whether the motor wiring is correct to eliminate the motor itself. 2.Overheating: The stepper motor driver may overheat when working for a long time or overloaded. Improve the heat dissipation conditions, add fans or heat sinks, ensure that the working environment temperature is suitable, and avoid long-term overload operation. 3.Excessive noise: Abnormal noise during motor operation may be caused by bearing damage or loose internal parts. Check whether the motor bearing is damaged, re-tighten the loose internal parts, and adjust the driver current setting. 4.Overcurrent protection: The driver has an overcurrent protection function. If the output current exceeds the rated value, the driver will cut off the power supply to protect the motor and itself. Check the power supply and motor load, and readjust the current setting. 5.Communication error: If the driver and controller are controlled by communication, communication errors may indicate that the driver cannot work properly. Check the communication line and settings to ensure stable communication.

4.Precautions for using stepper motor drivers

1.Power management: The quality of the power supply directly affects the performance and power consumption of the driver. The ripple size of the power supply affects the accuracy of the subdivision, and the suppression ability of the power supply common mode interference affects the anti-interference of the system. Therefore, for applications with higher requirements, users must pay attention to improving the quality of the power supply. In addition, the installation of the driver should ensure good ventilation, and regularly check whether the cooling fan is running normally. 2.Signal line processing: When wiring the system, the principle of separating the power line (motor phase line, power line) from the weak current signal line should be followed to avoid interference with the control signal. When it is impossible to wire separately or there is a strong interference source, it is best to use shielded cable to transmit the control signal. Using a higher level control signal is also meaningful for resisting interference. 3.Initial operation check: Do not connect all the lines at the beginning. You can connect the most basic system first, and then complete all the connections after confirming that it is running well. Carefully observe the sound and temperature rise of the motor. If any abnormality is found, it should be stopped and adjusted immediately. 4.Environmental adaptation: Due to the drastic changes in the storage and transportation environment temperature, condensation or frost is easy to occur. At this time, the driver should be placed for more than 12 hours. After the driver temperature is consistent with the ambient temperature, it can be powered on. If stored in an unsuitable environment for a long time, the quality of the product should be retested before operation.

Source:https://medium.com/@porterbickford69/solutions-to-faults-during-operation-of-stepper-motor-drivers-7fc1e964767f

0 notes

Text

When Your Garage Door Descends but Abruptly Halts: Causes and Remedies

We've all encountered the frustrating scenario: you press the button to close your garage door, it begins its descent seamlessly, but then, it halts and reverses! Rest assured, this issue is commonplace and easily rectifiable.

Your garage door might start closing only to stop due to obstructions in its path, misaligned sensors, or faulty components. Simply removing obstacles, adjusting the sensors, or enlisting professional help can resolve the issue.

Let's delve into the reasons behind your garage door's unexpected stops and how you can restore its smooth operation.

Causes of Garage Door Halting Mid-Close

Obstructions in the Path

Objects like toys, tools, or small stones can obstruct the door's path. Sensors detect these impediments and halt the door to avoid closing on something.

Sensor Misalignment

For proper closure, the sensors must be perfectly aligned. If they are bumped or displaced, misalignment occurs, causing the door to stop.

Dirty or Blocked Sensors

When sensors are dirty, their vision is impaired, causing the door to stop. It's akin to trying to see through smudged glasses; cleaning is necessary for clarity.

Broken Springs

The springs are essential for lifting the door. If they're broken or aged, the door becomes too heavy for the opener, causing it to stop.

Damaged Tracks

Smooth tracks are vital for the door's movement. Bent, damaged, or rusty tracks can cause the door to get stuck and halt.

Remote Control Issues

Dead batteries or a need for reprogramming in the remote control can cause the door to stop. Sometimes, the wall switch may also have problems.

Electrical Problems

Loose wires or faulty electrical components can disrupt the door's function. This usually requires professional intervention.

Remedies for a Garage Door that Stops and Reverses

Obstruction in the Path

What to Do: Inspect the area around the garage door for obstructions like toys, tools, or small stones. How to Fix: Remove any objects in the door's path. Tip: Keep the area around your garage door clear to prevent future issues.

Sensor Misalignment

What to Do: Check the sensors on both sides of the garage door. How to Fix: Most sensors have an adjustment screw. Carefully turn this screw slightly to realign the sensors. Small adjustments can make a significant difference. If unsure, call a professional. Tip: Periodically check the sensors to ensure they remain aligned, especially after any impacts or movements.

Dirty or Blocked Sensors

What to Do: Examine the sensors for dirt or dust. How to Fix: Gently clean the sensors with a soft cloth to remove any debris. Tip: Regularly clean the sensors to maintain their functionality.

Broken Springs

What to Do: Inspect the springs above your garage door for any signs of damage or wear. How to Fix: Due to the high tension in garage door springs, it's safest to call a professional if you suspect a problem. Tip: Have a professional inspect your garage door springs annually to catch issues early.

Damaged Tracks

What to Do: Examine the tracks on both sides of the garage door for bends, damage, or rust. How to Fix: Use a rubber mallet to gently straighten any bends. For severe damage, call a professional to replace the tracks. Tip: Keep the tracks clean and regularly check for damage to ensure smooth operation.

Remote Control Issues

What to Do: Ensure the remote control and wall switch are functioning properly. How to Fix: Replace the batteries in your remote control. If that doesn’t work, reprogram the remote following your garage door opener manual's instructions. Tip: Regularly check the batteries in your remote control and keep it clean and dry.

Electrical Problems

What to Do: Inspect the wiring and electrical components of the garage door opener. How to Fix: Look for loose wires or connections. If you’re not comfortable with electrical work, call a professional. Tip: Regularly inspect the electrical parts of your garage door opener for signs of wear or damage to prevent issues.

Consequences of Ignoring Garage Door Issues

Failing to address garage door problems can lead to more severe issues. A malfunctioning door can become an easy target for burglars. The motor might wear out and stop functioning. In the worst-case scenario, a broken spring could cause the door to fall abruptly.

Preventing Garage Door Problems

To avoid garage door issues, follow these simple tips:

Schedule Regular Maintenance: Have a technician inspect your door regularly for wear and tear.

Lubricate Moving Parts: Use a silicone-based lubricant on hinges, rollers, and tracks.

Clear Sensor Area: Keep the area around sensors clear to prevent obstructions.

Conduct Visual Checks: Inspect your door every few months for any damage or problems.

Conclusion

Dealing with a garage door that starts closing but stops can be frustrating, but the solutions are often straightforward. Regular maintenance and quick fixes can prevent more significant problems down the road. When in doubt, call a professional to ensure your garage door operates smoothly and securely.

0 notes

Text

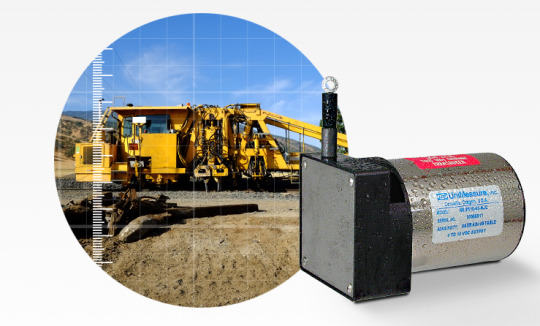

UniMeasure Inc

UniMeasure Inc

UniMeasure, Inc. has been manufacturing position and velocity sensors in Corvallis, Oregon since 1987. The company has steadily grown over the years to become a leader in the linear and rotary transducer industry with a focus on customer service, innovative design, and high-quality products. The Corvallis facility is ISO 9001:2015 certified with many raw materials and vendor services sourced in the local area. With a core group of long-standing employees, UniMeasure is dedicated to manufacturing position sensors in the USA and providing high-quality solutions while further enhancing customer experience.

UNIMEASURE LINEAR POSITION TRANSDUCERS

String Potentiometer

Often referred to as string pot, yo-yo pot, draw wire transducer, cable extension transducer, cable actuated transducer, UniMeasure extending wire rope linear position transducers have proven to be an attractive approach for a multitude of applications in many different industries. With relatively non-critical alignment requirements, compact size, and ease of installation wire rope actuated transducers are the linear position measurement system of choice in applications as diverse as bone densitometers in the medical industry, crash testing in the automobile industry, pump jacks in the crude oil extraction industry and irrigation and flood control in the water management industry. With a wide variety of electrical outputs, UniMeasure linear displacement measuring and position sensor products provide an extremely cost effective method for linear position feedback.

UNIMEASURE ROTARY POSITION TRANSDUCERS

Position Sensor

UniMeasure rotary position transducers provide an analog output signal that is directly proportional to the angle of rotation of the shaft of the device. With a voltage or 4 to 20 mA analog electrical output, UniMeasure rotary position transducers are also known as angle sensors, analog rotary shaft encoders and analog multiturn analog shaft encoders and absolute angle encoders. These position sensor devices are commonly used in applications where an absolute output signal is a must. Typical use occurs in closed loop process control and in testing applications where oscillatory rotary motion occurs. UniMeasure absolute analog rotary position transducers have proven to be an extremely cost effective alternative for measuring rotational positioning.

CONTACT US

UniMeasure Inc https://unimeasure.com/ ADDRESS: 4175 SW Research Way Corvallis, OR 97333 PHONE: (541) 757-3158

Facebook

1 note

·

View note

Text

China supplier MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B power plant spare parts